The marvel of modern engineering is built on the shoulders of giants, with roots in everything from the wheel to the silicon chip. It’s a rich tapestry that binds together everything from vehicles to home appliances, all made possible by a network of complex parts and pieces. Among these integral parts, hidden within the heart of motors and alternators, resides the unsung hero of electromechanical devices: the stator.

A Brief Overview

Simply put, a stator is a stationary component of an electric generator or motor built with tightly wound coils of wire. These devices work with the rotor (the moving part of the motor) to convert energy. In a motor, electric energy is converted into mechanical energy, and vice versa in a generator. The stator’s role in this energy dance is pivotal.

In a conventional setup, the rotor turns within the stator. As the rotor moves, it creates a rotating magnetic field, inducing a flow of current in the stator coils. This current is then utilized to power the device in question. Stators find themselves at home in a myriad of devices such as automobiles, ceiling fans, wind turbines, and even in the humble washing machine.

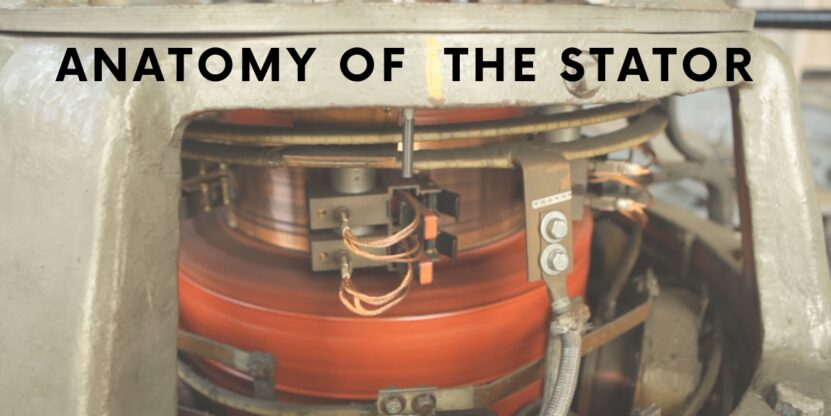

A Closer Look at the Anatomy of This Device

This device typically consists of three primary parts:

- Core: The stator core is a large cylinder made of stacked laminations of thin metal. This design helps to reduce energy loss through eddy currents.

- Windings: These are the insulated wire coils wound around the core. The flow of current through these windings generates the magnetic field that interacts with the rotor.

- Frame: The frame is the structure that holds the core and windings in place. It also helps to dissipate heat produced by the motor operation.

It’s clear that stators are workhorses of the electromechanical world. But like all things mechanical, they, too, are prone to failures. Overheating, voltage overload, dirt accumulation, and physical damage can all lead to a stator’s untimely demise.

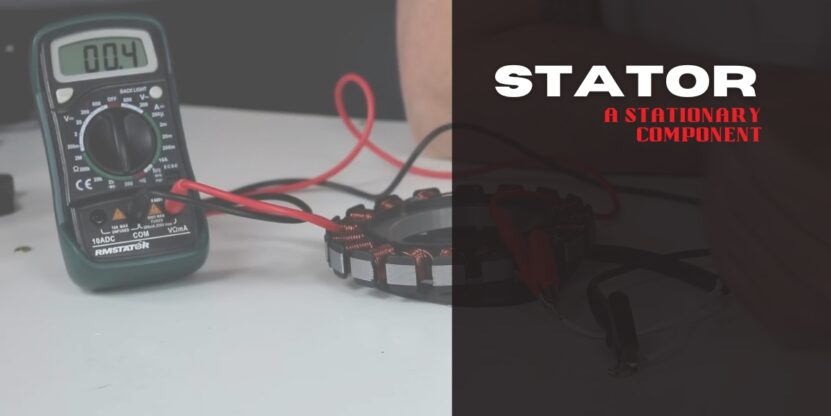

Health Check: Testing with a Multimeter

Fortunately, we have multimeters and versatile tools capable of testing for many electrical faults, including those found in stators. Whether you’re an expert mechanic or a DIY enthusiast, understanding how to use a multimeter to test a stator is an invaluable skill.

Step 1: Understand your Multimeter

A multimeter is a device that measures electric current, voltage, and usually resistance, typically over several ranges of value. To test a stator, we’ll use the multimeter’s ohmmeter setting, which measures resistance in ohms (Ω).

Step 2: Access the Stator

Before you can begin testing, you must access the stator. Depending on the device, this may involve removing an outer casing or cover. Always ensure the device is turned off and unplugged to avoid electrical shock.

Step 3: Identify the Stator Wires

Locate the wires coming out of the stator. There are usually three of them in a three-phase system, but it may differ based on your device. Check your device’s manual if you’re unsure.

Step 4: Set the Multimeter

Set your multimeter to the lowest ohms setting. This is often represented by the Greek letter Ω on the multimeter.

Step 5: Testing for Resistance

Take your multimeter’s probes and touch the terminals of two stator wires. Note the reading on the multimeter. This process should be repeated for all combinations of the stator wires (i.e., Wire 1 to Wire 2, Wire 2 to Wire 3, Wire 1 to Wire 3). All readings should be relatively similar and within the specified range in your device’s manual.

Step 6: Testing for Grounding Issues

Finally, you should test each wire against the stator core or frame to see if there are any grounding issues. One probe should touch a stator wire while the other touches the stator core or frame. The multimeter should ideally show an infinite or ‘overload’ reading, indicating no continuity between the wire and the frame. If there is a reading, this suggests a ground fault, meaning the stator is likely damaged.

Warning: Always exercise caution when working with electrical systems. If you’re unsure about any part of the testing process, consult a professional.

The Evolution

It’s worth taking a step back to understand the stator’s evolution. The journey of this humble component mirrors our own technological advancements, offering a fascinating glimpse into our shared history.

Stators, like many aspects of engineering, have evolved alongside human innovation. The ancient Egyptians used primitive stators in their rudimentary water pumps, showing an early understanding of the principles of rotary mechanics.

However, this device as we know it today came into existence in the late 19th century with the advent of the electric motor. Michael Faraday, known as the ‘Father of Electricity,’ laid the foundation for this development with his pioneering work on electromagnetic induction.

Applications: Beyond Motors and Generators

While stators are key to motors and generators, their influence extends far beyond these applications. They are integral to alternators in our vehicles, powering our headlights and charging the battery as we drive. They’re also found in the magnetos of small engines, like those in lawnmowers and motorcycles, generating the spark needed for combustion.

Wind turbines, too, are powered by giant stators, converting the kinetic energy of the wind into electricity we use to light up our homes. Even in the field of robotics, stators find their place in servo motors, enabling precise control for intricate operations.

A Glimpse to the Future

As we stand on the brink of a renewable energy revolution, the importance of the stator is more pronounced than ever. Advances in material science are leading to more efficient and durable stator designs. With the rise of electric vehicles and a growing emphasis on energy efficiency, the humble stator is poised to play an even more significant role in our future.

As our world becomes more interconnected, the demand for efficient power conversion will only grow. In this landscape, stators will continue to be a key player, quietly powering our journey into the future.

Closing Thoughts

At first glance, the stator might seem like just another cog in the grand machine of electromechanical devices. But a deeper look reveals its crucial role in the symphony of power conversion. Understanding the stator and its workings enhances our appreciation of the marvels of engineering around us. Plus, learning to test a stator with a multimeter brings us closer to the heart of our devices and empowers us to keep them running smoothly.

As we flip switches, rev engines, and power up devices, let’s give a thought to the humble stator, working diligently behind the scenes to bring power to our lives. After all, without these devices, much of the modern world would come to a grinding halt!